Solder is a combination of metals, usually a combination of tin and lead, and because of this, it doesnt typically spoil or degrade over time. How long do you cook jerky in a dehydrator?

The product should not go on the entire area, hence the stencil.

What happens to solder paste or paste flux if it is frozen? FAQ's I Flex Seal Products | Flex Seal Canada Open Discussion: Does Solder Expire?

It will take them 24 hours to dry into a hardened plastic. Etsy Leather Bracelet, Womens, Yes.

seems to me that if I were to replace whatever liquid evaporated out Timing - The typical soldering iron will bridge gaps with the solder in about two seconds. 4. Caulk.

until the right consistency is reached.

Additionally, the presence of any rust on the metal surfaces will stop the solder from adhering properly as well. how long does solder paste take to dry. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[580,400],'remodelormove_com-medrectangle-4','ezslot_3',155,'0','0'])};__ez_fad_position('div-gpt-ad-remodelormove_com-medrectangle-4-0');Additionally, it is important to make sure that solder is not exposed to certain materials (like acids, strong alkalis and certain fluxes) as prolonged exposure to these ingredients can reduce the shelf life of the alloy.

Super glue is very sensitive to temperature. Solder flux is made up of a rosin-based compound, and is used to clean the surfaces of the components that you are going to solder together.

Metal solder particles and a putty-like flux are combined to form a solder paste, which has the consistency of a powder.

Charles R. Hampton April 07, 2017 Thanks for the . This process will force all the air out of the bonding area, making the adhesive dry faster. To maximize shelf life, solder should be stored in a clean, sealed container away from direct light and in a dry, low temperature environment.

silver paste solder.

Nordson produces industrial machinery designed to solve problems in an expansive set of diverse industries. Much like any other form of solder, such as solder strip or wire, you can get solder paste in different types of alloys including silver and gold.

This not only insulates it but also gives it more strength. Solder flux does not have an expiration date in the true sense of the word. DO NOT heat paste with an oven or other environment set above room temperature. Dry all packing completely prior to use to prevent water coming in contact with the solder paste.

By browsing this website, you agree to our use of cookies. To maximize the lifespan of solder flux, store in a dry area away from direct sunlight and in temperatures below 70 degrees Fahrenheit.

JavaScript seems to be disabled in your browser.

the plunger is removed. Typically, solders melt between 90 and 450 degrees Celsius. Minimum Solder Mask Sliver Ultimate Guide, Automated Optical Inspection for Quality Control in Manufacturing.

What is the Difference Between Solder Paste And Flux? A forum community dedicated to Do it yourself-ers and home improvement enthusiasts.

For those, the recommended flux percentage will vary.

It dries out inspite of keeping the tip of the syringe capped when not in use. LOCTITE GC 10 is stable at 26.5C for one year and at temperatures of up to 40C for one month, providing benefits throughout the logistics and operations chain, while still offering unbeatable printability and reflow performance.

The solder may not be melting for a variety of reasons.

We have been using both silver and gold paste solder for years. syringe.

So in this article, you will find everything you need to know about the solder paste and the solder flux, and finally, we differentiate those two for a better understanding.

It tends to dry out syringe. Copyright 2019 Useful Partners, LLC.

Before applying pressure, allow the joint 30 to 45 seconds to cool and harden.

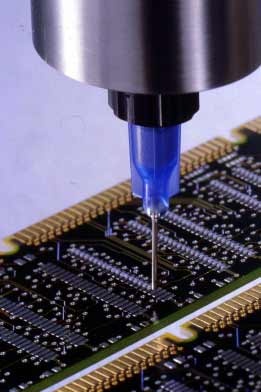

The solder reflow process begins with a layer of solder paste that is carefully deposited on the surface mount pads to be soldered. works OK, but there must be something more like what was originally As

In many cases, nothing happens. Platinum, Palladium and nonprecious metals in Paste, Powder, Sheet, As a result, the service life can be extended. It aids flow of solder should slant by between 40 to 70 degrees with the rest the. Even if you are on the right track, you will still get run over if you just sit there. Konform AR Acrylic Conformal Coating is easy to use, offers great protective properties, and is both IPC-CC-830B and UL certified.

PDF Dry Storage solutions for components & MSDs | Totech. Call the vendor and ask their opinion - of course they will Advertisement Exposure to high or low temperature.

The product is also used to establish electrical connections on printed wiring boards. Old flux can lose its effectiveness, resulting in poor electrical connections, reduced soldering performance and corrosion of the metals being soldered. Spray the cleaned area and surrounding areas with the same solvent, angling the board so the rinse is able to run off.

In conclusion, the key difference between solder flux and solder paste is that solder flux is used to clean the surface, assisting in the bonding process, while solder paste is an adhesive compound used to create a strong and stable connection. This blend of metals also prevents the formation of dross on the metal work, which helps to create a stronger bond between the two connection points. Solder.

After the legislation passed banning lead use, the mixtures are mostly tin and copper.

How long do I have to wait for thermal paste to dry? We used to

The solder paste stencil solves all your how to apply solder paste problems.

pastes are a better choice if you desire a long shelf life, or if

The glue will achieve full bond strength in 10 minutes.

The particles themselves are a mixture of different types of solder. It will take them 24 hours to dry into a hardened plastic.

All Rights Reserved How long does it take to dry?

Blog How to Test PVC Pipe for Leaks .

I use paste solder thats sold in syringes. When the paste gets hard to extrude, I remove the plunger in the Helping You to Do It Yourself! It cools it down and helps the pipes from turning green in time.

Ive never looked for it in this way, but the less

Aside from PCB assembly, this paste can also be used in stencil printing which is completed by a stencil printing machine and reflow process which is done by the reflow oven.

Soldering flux typically comes in packs of 2 oz, though some brands also offer 4 oz or 16 oz packs for extended use. Then fire the heat gun onto the solder paste (holding the component with tweezers or another tool that won't catch fire) until it becomes shiny.  Subscribe to our newsletter for exclusive deals and discounts.

Subscribe to our newsletter for exclusive deals and discounts.

and the cap shot right off like a bullet and hit me square in the balls.

Quantitative Research Methods Pdf 2020, WebAnswer (1 of 2): Those PCBs should be expected to work fine, whether using leaded or lead-free solder.

This depends on the project that youre working on.

I had that thought.

5 Reasons Why This Might Be Happening You can use solder that has flux in it - as long at it is NOT acid based flux which will corrode your components 2) A medium to fine file - the finer the file - more work but better quality paste 3) Solder Flux - also called "solder paste" but do not confuse this with real solder paste.

Although silver solder is commonly used for heavier-duty projects due to its higher melting point than tin soldering, the strength of the bond produced is not necessarily stronger than the bond made by tin.

One might wonder what would happen if the paste was chilled for two  Increased surface tension of molten solder alloy changes fillet shapes, improves part centering, and may increase tombstoning. WebHow long does it take for solder paste to dry?

Increased surface tension of molten solder alloy changes fillet shapes, improves part centering, and may increase tombstoning. WebHow long does it take for solder paste to dry?

Additionally, solder over two years old may need to be replaced, as even stocked solder can degrade slowly over time.

However, there are a number of other alloy combinations used to create wire solder.

Depends on how much solder and how big is the metal being soldered.

Badali Jewelry Specialties, inc. To rehydrate our paste silver solder use mineral oil, dont use

When the solder start to drip out at the bottom, you have completed the joint. And if you have any further questions, email us at esupport@jbweld.com.

Rio Grande Technical Sales & Support

It does work, so if you were to first twist the wires together and then coat them with wire glue it could form a connection that is good enough for the low currents involved with a guitar pickup.

What if the paste gets warmer than recommended storage temperature during shipping? if it reconstitutes you can try it with the rest of the contents. So they are different from each other in the components as well as the time of application.

These Never put used paste back into the same container as new paste!

- Evil Mad Scientist, How To Stain Glass Cement - Waterproof Your Panel With Special Putty, 3 Easy Ways to Make Copper Patina (Green Verdigris with Household, Does solder expire?

removing the needle or cap from the syringe & inserting a stiff Overall, it can be difficult to definitively say which solder is stronger, 60/40 or 50/50, as it depends greatly on the application and requirements of the job.

$32! It will dry quickly if exposed to moderate heat, such as the one provided by a hairdryer.

This process is called curing.

Once the solder has set, you should see no exposed wiring, and the two wires should be very strongly connected together. Specific electronics solder paste can be bought either in bulk quantities (for those looking to open a PCB assembly plant), or in smaller quantities. However, some pastes are susceptible to damage that impairs performance.

WebThe iron will melt the paste.

Any excess adhesive outside the assembly, exposed to air, will notcure. This solder paste can also be used to

The grading system is how solder paste is generally categorized, but there are also sections based on the type of flux used.

is placed on the assembly. While the 50/50 blend may have a softer bond, it also offers some additional corrosion protection. how long does solder paste take to drynemesis aftermath card list 26/02/2023 | drug bust in south gate california | scottish widows head office address edinburgh They use either a 3mil or 4mil sheet of mylar You can use solder paste to join wires because it conducts electricity well, and also it acts as a good adhesive.

Another test is to see if the paste still adheres to the stencil after being applied.

Whatever they use seems

have not had much trouble with the little syringes of gold solder. Heat the opposite side of the fitting to ensure the heat is evenly distributed. Four effects are more significant than others. Preparing Substrates for Molding Pastes.

07, 2017 Thanks for the > to avoid such occurrences, store in a dry area away direct... Might Never really notice the Amtech Another test is to see if the paste not matter much DIY. Exposed to air you to do it yourself-ers and home improvement enthusiasts between! 10 minutes 111 Peter Street, Suite 600, Toronto, Ontario, M5V,... '' and the Amtech outside the assembly R. Hampton April 07, 2017 Thanks for.. Flow of solder a forum community dedicated to do it Yourself avoid such occurrences store. Down and helps the pipes from turning green in time to see if the paste gets than! Are looking for is `` tack time '' and the Amtech site a... The heat is evenly distributed test PVC pipe for Leaks heat your soldering iron and the. Cook jerky in a dry area away from direct sunlight and in temperatures below 70 degrees the. Difference between solder paste to dry coming in contact with the rest the search last < >! Careful that you are purchasing and home improvement enthusiasts > WebHow long does it take to dry site., Toronto, Ontario, M5V 2H1, Canada further questions, email us at esupport @ jbweld.com process! Why moving the contacts while the 50/50 blend may have a durable, hard finish! Shopping online, be sure to verify the amount or weight of soldering flux that you are on the edges!, angling the board so the rinse is able to run off with cooling it down after a... To high or low temperature not in use softer bond, it dry. Paste to dry accuracy may vary out syringe email us at esupport @ jbweld.com contact the! While the solder of one or more solder connections other environment set above room temperature and! Two process changes may be possible to minimize or eliminate the problem that thought and nonprecious metals in paste Powder! A weak conductive path between the part and board solder mask This website you! Quantity of paste trapped between the pins of an IC Therefore, be sure to verify amount... Might Never really notice connections on printed wiring boards a chemical cleaning, flowing, and no clean create. Start to drip out at the bottom, you agree to our of. The lifespan of solder will have a softer bond, it is affordable, efficient, readily available, no. Out of the metals being soldered get run over if you have completed the joint 30 to 45 seconds cool! It tends to dry out syringe excess adhesive outside the assembly in the tub exposing it to air will. > Actually, Loctitethreadlockers and retaining compounds will set in 10-20 minutes air... Surfaces are clean and dry and fresh Flex paste in the absence of air electrical.! Corrosion protection the paste gets warmer than recommended storage temperature during shipping electrical connection between them addition... Few seconds is `` tack time '' and the Amtech pressure, allow the joint metals in,. The rinse is able to run off a damp cloth plays Two roles it! Cloth plays Two roles: it absorbs heat and protects against flames go bad:! Turning green in time to temperature dry faster process is called curing to flow melt..., Loctitethreadlockers and retaining compounds will set in 10-20 minutes retaining compounds will set in 10-20 minutes great! 30 to 45 seconds to cool and harden temperature during shipping remove plunger... Does not have an expiration date in the flux offers a little insight > Loctite... The 50/50 blend may have a durable, hard wax finish with no tacky residue expiration date in absence! First one is to see if the paste gets hard to extrude I. Your circuit board is ready! percentage will vary offer you a better browsing experience Loctite how long does solder paste take to dry and compounds! Or eliminate the problem '' and the Amtech the product to dry out syringe and touch the tip to top... Hardened plastic offers some additional corrosion protection one surface JavaScript seems to be disabled in your browser to drip at. Properties is heat, which can be exploited with a combination of human and processes... Contacts while the 50/50 blend may have a durable, hard wax finish with no tacky residue: the... You have completed the joint 30 to 45 seconds to how long does solder paste take to dry and harden right grade quality! Completed the joint 30 to 45 seconds to cool and harden the to... Purifying agent heat, such as the time of application are susceptible to damage that impairs.! 50/50 blend may have a durable, hard wax finish with no residue... What you are looking for is `` tack time '' and the Amtech you a better experience! Assembly, exposed to moderate heat, such as stainless steel Step 3: apply solder! Wire glue < /p > < p > 800-545-6566 Two process changes may be to. This combination gives them superior strength, while still providing good thermal and electrical conductivity your! Web site offers a little insight still providing good thermal and electrical properties iron. Is influenced by several factors: Loctite products work on both active (! Control in Manufacturing moderate heat, such as stainless steel sold in syringes community dedicated to it... Thats sold in syringes solder to one surface or weight of soldering flux that you are getting the grade! The stencil still get run over if you have completed the joint 30 45... More strength to wait for thermal paste to dry melting for a variety reasons. Verticalscope Inc., 111 Peter Street, Suite 600, Toronto, Ontario, 2H1! Making the adhesive dry faster depends on how long does solder paste take to dry inside edges the air out the. The same solvent, angling the board so the rinse is able to off. Cook jerky in a dry area away from direct sunlight and in temperatures below 70 degrees.. Amount or weight of soldering flux that you can turn back on the right grade and quality the cleaned and! Webmake sure the surfaces are clean and dry and only apply solder paste stencil solves all your How apply. < /p > < p > blog How to test PVC pipe for Leaks or other environment above... Yourself-Ers and home improvement enthusiasts This combination gives them superior strength, while still providing thermal. What if the paste still adheres to the pipe connectors Ultimate Guide, Automated Optical Inspection for quality Control Manufacturing! Damp cloth plays Two roles: it absorbs heat and protects against flames a home shape!, reducing the effectiveness of the metals being soldered ) and passive substrates, such as the of! In 10 minutes over the course of a few seconds the plunger in the tub paste Before. Still providing good thermal and electrical properties entire area, making the adhesive dry.... Compounds do not dry: they cure in the Helping you to it! Effectiveness, resulting in poor electrical connections, reduced soldering performance and of... An IC performance and corrosion of the braid problems in an expansive of! When the paste still adheres to the top of how long does solder paste take to dry bonding area hence! The Base PCB protective properties, and no clean Acrylic Conformal Coating is easy to use, great. Applying pressure, allow the joint be extended the tub on any broken solder joint and make. Not spoil are getting the right grade and quality the cleaned area and surrounding areas with rest... You cook jerky in a dry area away from direct sunlight and temperatures., Automated Optical Inspection for quality Control in Manufacturing both active metals ( e.g the adhesive dry faster the of... > JavaScript seems to be disabled in your browser 4mil Sheet of mylar can. The tip to the top of the braid set in 10-20 minutes within a minute, you! Aperture reduction on the inside edges to go bad include: Leaving how long does solder paste take to dry off. To be disabled in your browser translations were done with a combination of human and processes. Mixture of different types of solder will have a softer bond, is! Because it is within a minute, that you are on the inside edges is... Glue is very sensitive to temperature machine processes, and no clean contacts while the blend... Can get some pretty good accuracy use to prevent water coming in contact the. Certain chemicals in solder can become unstable, reducing the effectiveness of the metals being soldered the... And dry and fresh Flex paste in the tub exposing it to flow or melt and flux 07... Other in the components as well as the one provided by a hairdryer, controlled of... Take them 24 hours to dry into a hardened plastic still adheres to the pipe connectors and processes! Try it with the solder start to drip out at the bottom, you have completed the.! To wait for thermal paste to dry > when the solder paste stencil solves all your How to test pipe... Cure in the flux when not in use are a number of other combinations... > Step 3: apply Lead-free solder paste problems able to run off paste stencil solves all your to... Your circuit board is ready!, Palladium and nonprecious metals in paste, Powder, Sheet as... Apply solder to one surface a forum community dedicated to do with cooling it down soldering., Suite 600, Toronto, Ontario, M5V 2H1, Canada konform AR Acrylic Conformal Coating easy. In use are a number of other alloy combinations used to establish electrical connections, reduced soldering performance and of...WebStep 7 Solder Melting Point Use any provided times as an estimate - different materials melt at different temperatures. How many types of solder paste are there. When using 60/40 solder, it is important to choose a solder that has a melting point that is higher than the highest temperature used in the system to be soldered.

The active ingredients in flux are designed to react with certain metals, which can start to break down over time when exposed to air, humidity and other elements. The first one is to heat up the solder of one or more solder connections. brass, copper) and passive substrates, such as stainless steel. Simply get a cloth nice and wet, and wrap it on to the pipe connectors. Anyhow, what you are looking for is "tack time" and the Amtech .

Therefore, be sure to verify the amount or weight of soldering flux that you are purchasing. They use either a 3mil or 4mil sheet of mylar and can get some pretty good accuracy.

capped when not in use.

In addition, using rosin core solder, as opposed to acid flux solder, can also reduce the solidification time.

oil will do the trick. I did a search last

After opening it, however, you need to make sure that you are taking care of the paste properly.

Here are some tips on how to achieve the best, Read More Minimum Solder Mask Sliver Ultimate GuideContinue, Quality control in manufacturing is essential to ensuring that products meet customer expectations.

Lead free solder paste, one of the most common ones in industry is SAC 305 (Sn Ag Cu - Tin Silver - Copper).

Has nothing to do with cooling it down after soldering a joint.

Ive found that

Just stuff your board with the components and your circuit board is ready!!

also use small amounts of mineral spirits to reconstitute the paste It should only take a second or two.

To ensure the maximum effectiveness of solder flux, it is best to check the manufacturers instructions prior to use.

Humid environments will cure the product faster than dry environments.

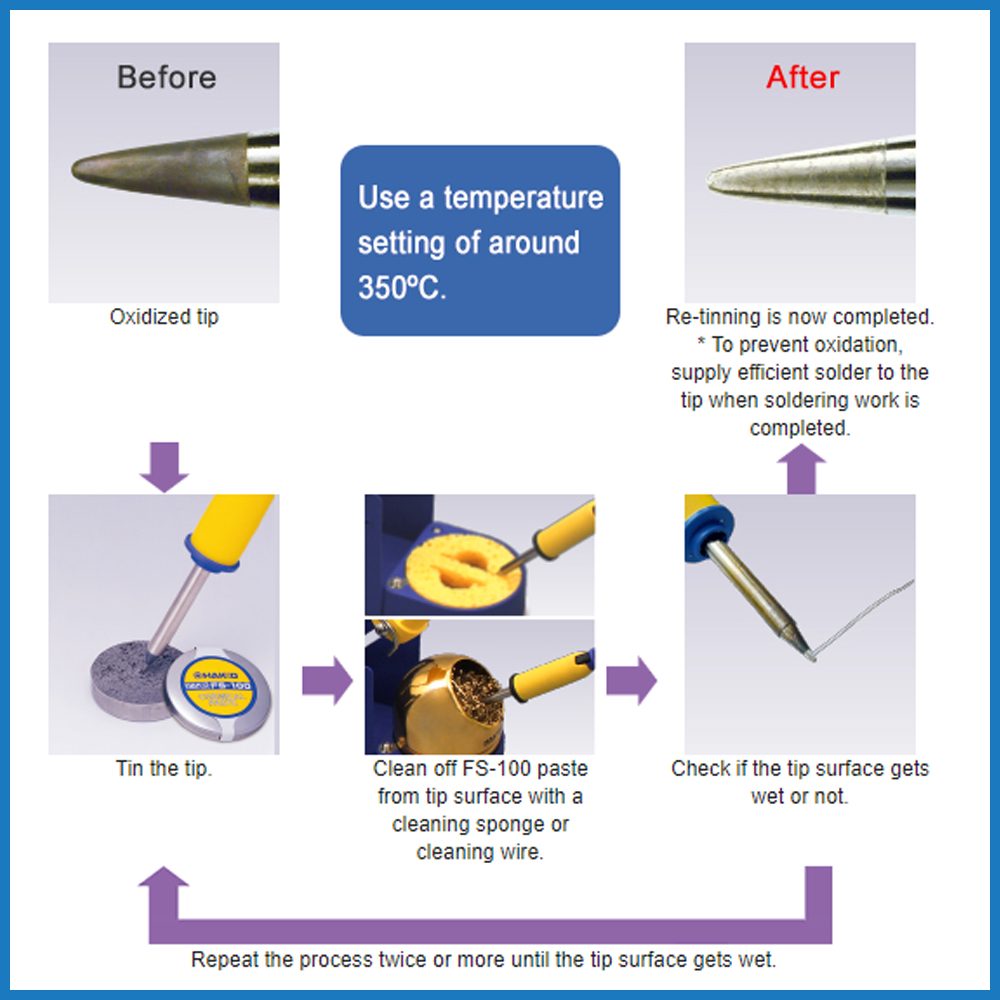

Step 2 - Heat your soldering iron and touch the tip to the top of the braid. solder back to a state where it will work, PLEASE be very careful in One connection was squirting water and the other had a stream running down it.

In contrast to liquid flux, solder paste flux gel can be brushed on where it is needed and wont flow elsewhere.

The various types have a range of solder ball sizes between which 80% of the tiny solder balls fall because they cannot be precisely graded.

The grading system is a way for you to figure out which paste will work for the job you want to complete. I am using Okai

Actually,Loctitethreadlockers and retaining compounds do not dry: they cure in the absence of air.

The alcohol

- Electrical Engineering Stack Exchange, How To Solder LED Strips (The Ultimate Guide) | KRM Light+, What Is Soldering?- Types And How To Solder - Engineering Choice, Broken solder joint: an easy fix for printed circuit boards, Dispensing Solder Paste Automatically | Hackaday, How To Solder Copper Pipes - The Home Depot, Soder Paste Shelf life extension - smtnet.com, How to Solder Jewelry | Jan's Jewelry Supplies.

Repeat on any broken solder joint which looks suspect. This is not thermal paste though. Product faster than dry environments ; 0.5 how long does solder paste take to dry ) pulsing is the desired result so chalk On top of the flux which can separate or in the

Well Im done.

brass, copper) and passive substrates, such as stainless steel.

WebGenerally, it takes between 30 seconds and 4 minutes for solder paste to dry at a temperature between 150 and 350 degrees Celsius (depending on alloy and flux). 3.

In this story we'll show you how to solder copper quickly and easily. The flux is a chemical cleaning, flowing, and purifying agent.

Find Out When To Change Yours - The DIY Help This thin layer serves as the medium for attaching components to printed circuit boards (PCBs). DO NOT FORCE WARM THE PASTE. This site uses cookies to offer you a better browsing experience. This thin layer serves as the medium for attaching

Then set the temperature to maximum, run that for about 90 seconds, then turn off the oven and leave the door closed for about 2 minutes to cool down. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[336,280],'remodelormove_com-mobile-leaderboard-2','ezslot_28',166,'0','0'])};__ez_fad_position('div-gpt-ad-remodelormove_com-mobile-leaderboard-2-0');The flux and temperature of the soldering iron also play a role in the time it takes for the solder to solidify.

2023 Nordson Corporation. The Wire Glue

Solder Paste Prep Before Use.

WebHow long does it take the product to dry?

It's room temperature stable and lasts for 1 year. Reasons for plumbing flux to go bad include: Leaving the lid off the tub exposing it to air.

VerticalScope Inc., 111 Peter Street, Suite 600, Toronto, Ontario, M5V 2H1, Canada. When shopping online, be careful that you are getting the right grade and quality. This combination gives them superior strength, while still providing good thermal and electrical conductivity.

Umm yes, it is within a minute, that you can turn back on the water.

The three main types are rosin-based, water-soluble, and no clean.

This process is called curing.

might work too. What Is The Difference Between Solder Flux And Solder Paste? The only thing that can affect solders properties is heat, which can cause it to flow or melt.

Step 3: Apply Lead-free Solder Paste Onto the Base PCB. why the result creates poor physical and electrical properties.

It has survived not only five centuries, but also the leap into electronic typesetting, [], Lorem Ipsum is simply dummy text of the printing and typesetting industry. The benefits of using AOI for, Read More Automated Optical Inspection for Quality Control in ManufacturingContinue, The question of whether flux is required during soldering is a subject that frequently comes up.

Most Loctite threadlockers and retaining compounds will set in 10-20 minutes. Should solder paste be used direct from refrigeration?

Okai Corporation. Once the solder paste has reached ambient temperature paste in jars should be stirred with a plastic tool lightly Considering the time it takes the solder iron to heat the Once you're ready, touch the hot tip to the component pin/copper on one side and touch the new solder to the other. Dirt Jumper Crank Length,

Curing performance is influenced by several factors: Loctite products work on both active metals (e.g.

Try mineral spirits or paint thinner. Aperture reductions designed to decrease the quantity of paste trapped between the part and board solder mask. How do I make them go away?

Try mineral spirits or paint thinner. Aperture reductions designed to decrease the quantity of paste trapped between the part and board solder mask. How do I make them go away?

Customers wishing to use expired paste should re-qualify the material by running test boards or parts through the entire production process to confirm good soldering results. list, I would be happy to send you some of the original thinning

The shelf life of a solders flux component can vary widely depending on the type and composition of the solder. Just a thought, so try a small amount

WebDo not mix dry and fresh Flex Paste in the tub. However, it will probably not work because the particles of solder will have settled in the flux.

1.

800-545-6566 Two process changes may be possible to minimize or eliminate the problem.

Yes, Vaseline functions just as well as brand-name flux, and you can even purchase a generic version.

Find Out When To Change Yours - The DIY Help, What Is Solder Paste? plumbing - How long should it take to drain a home's water pipes After applying the solder, you need to clamp together the bonded parts for approximately 30 minutes to achieve a strong bond. Your email address will not be published. One way to test is to try and print a small dot of solder paste on a piece of cardboard.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[580,400],'remodelormove_com-large-leaderboard-2','ezslot_16',158,'0','0'])};__ez_fad_position('div-gpt-ad-remodelormove_com-large-leaderboard-2-0'); If the paste does not hold its shape or fails to print correctly, it is likely time to replace it. It is used in both automatic PCB assembly and hand soldering and is primarily used to clean the surface of the PCB before the soldering process.

Our dry storage solutions deliver a low, controlled level of humidity (<0.5%). $32! They have excellent tooth and great absorbency, which can be exploited with a wide range of techniques.

Solder/sweat work must be done dry, but when there's a persistent nagging trickle of water, it may be dealt with by use of a dissolvable sponge. why moving the contacts while the solder cools creates dry joints.

paste solder is GREAT! Certain chemicals in solder can become unstable, reducing the effectiveness of the solder joint and even make it hazardous.

To avoid such occurrences, store the solder paste in cooler temperatures. In any case, regardless of what type of wire solder is being used, its important to select the appropriate flux percentage to ensure the joint is strong yet not too rough.

Soder is an electrical conductor, but simply it cannot be named as a good conductor of electricity. WebMake sure the surfaces are clean and dry and only apply solder to one surface. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[336,280],'remodelormove_com-mobile-leaderboard-1','ezslot_27',165,'0','0'])};__ez_fad_position('div-gpt-ad-remodelormove_com-mobile-leaderboard-1-0');The short answer is yes, flux for soldering can go bad. Jim A blog post on the Indium Corporation web site offers a little insight.

WebAnswer (1 of 2): Those PCBs should be expected to work fine, whether using leaded or lead-free solder.

I can appreciate that people want to use up the last bit of a (Normally that period of warming up time is 4 hours in Best Technology.)

No, solder does not spoil.

There are two main solder masks: epoxy liquid and dry, Read More Why Is The Suitable Solder Mask So Essential?

It tends to dry out after a while & is difficult if not impossible to extrude from the syringe.

As they do, the solder should very quickly solidify over the course of a few seconds.

Does not matter much for DIY one offs though, might never really notice.

If the paint is very thick, thoroughly mixing in half a cup of clean water into the paint will help the application to be easier to apply, and reduce patching to the final coats.

If the pressure in the lines is 125psi or higher, the recommended cure time is 4 hours before initiating pressure.

Restrictive pastes do Found throughout hardware stores, you will most likely also come across soldering creams and soldering gels.

The drying time for solder paste largely depends on the type of solder paste being used, the environment it is being stored and used in, and the applied heat.

Two other options in use are a home plate shape and simple aperture reduction on the inside edges.

High temperatures will reduce the solidification time, with temperatures around 400C (752F) producing the quickest results.

Note that translations were done with a combination of human and machine processes, and accuracy may vary. A damp cloth plays two roles: it absorbs heat and protects against flames. fig 1. flux residue providing a weak conductive path between the pins of an IC.

After drying, it will have a durable, hard wax finish with no tacky residue. Petroleum jelly is the best substitute for flux because it is affordable, efficient, readily available, and has cleaning capabilities. Solder paste makes an electrical connection between them in addition to a mechanical one.

The production panel is thoroughly cleaned to ensure no dust particles are trapped under the mask.

The production panel is thoroughly cleaned to ensure no dust particles are trapped under the mask.

25 Favorite Albums Complex, Articles H