\u00a9 2023 wikiHow, Inc. All rights reserved. Central Pneumatic 2HP 8 Gallon air compressor. The air compression system uses pressure valves. So, go for a long-lasting solution and properly fix the damaged area through welding. If something should happen to them, you cant simply go online to buy a replacement. We will replace the reed valve in 4 following steps: If you have an old air compressor, then there is a possibility that the reed valve has become rusty. The pressure regulator knob is often right below or beside this gauge where it connects to the airline, though sometimes it is in between the 2 gauges. First, you must pump it down to above 80 psi. Sometimes, the air can be leaking on the drainage valve and that will not cause your air compressor to stop. I have seen many compression systems with pressure build-up problems.

Your air compressor cant supply any more air pressure than it has in the tank and it wont go above the maximum pressure set by the manufacturers pressure switch. Check Valves are tight. Manage Settings Close the drain valve and the tanks outlet valve to allow only air intakes. The only way to fix it is by welding the area because if you use any other type of solution it will not work.

Your air compressor cant supply any more air pressure than it has in the tank and it wont go above the maximum pressure set by the manufacturers pressure switch. Check Valves are tight. Manage Settings Close the drain valve and the tanks outlet valve to allow only air intakes. The only way to fix it is by welding the area because if you use any other type of solution it will not work.  How can you troubleshoot this issue? This image may not be used by other entities without the express written consent of wikiHow, Inc.

How can you troubleshoot this issue? This image may not be used by other entities without the express written consent of wikiHow, Inc.

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/3\/38\/Set-Air-Compressor-Pressure-Step-15.jpg\/v4-460px-Set-Air-Compressor-Pressure-Step-15.jpg","bigUrl":"\/images\/thumb\/3\/38\/Set-Air-Compressor-Pressure-Step-15.jpg\/aid12055259-v4-728px-Set-Air-Compressor-Pressure-Step-15.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\u00a9 2023 wikiHow, Inc. All rights reserved. This part is commonly misdiagnosed and the actual problem is a broken reed valve. A leaking tank can render your air compressor hard to use or it could even make the air compressor dangerous to work with at some point. #1. Look just above this and locate the plastic shroud covering the pressure switch. How to Fix an Air Compressor That is Not Building Pressure. This kind of problem can often lead to additional secondary issues like piston ring failure due to the incorrect function of the valve. With 200 maximum PSI, this air compressor provides 76% more air tool runtime versus 30 gallon 155 PSI compressors. No matter what brand of compressor you have, its a fact that at some point a part on it will fail. If your air compressor is being slow to build pressure, you need to read on for more information. Web3 Gallon 1/3 HP 110 PSI Oil-Free Hot Dog Air Compressor $6999 Was $ 74.99 Save 6% Add to Cart Add to My List NEW MCGRAW 29 gallon, 1.8 HP, 165 PSI Oil-Lube Vertical Air Compressor $59999 In-Store Only Add to My List FORTRESS 2 Gallon 135 PSI Ultra Quiet Hand Carry Jobsite Air Compressor $19999 Add to Cart Add to My List FORTRESS Air compressors that are slow to build pressure can be experiencing this issue for a variety of reasons. You will need to ensure that the drainage valve is closed perfectly at all times. Would you like to bid that amount now? Shipping Weight 18.04 lb.

Apart from weather effects, the common cause of an air tanks corrosion is the residual water from condensate. If you would like to change your settings or withdraw consent at any time, the link to do so is in our privacy policy accessible from our home page.. Save 5% with coupon. Is it? wikiHow, Inc. is the copyright holder of this image under U.S. and international copyright laws.

We feel proud to solve user issues they face while using different mechanical tools. He loves to study and work on mechanical tools.

Qty. A little smoke can help visualize this. Gasket issues can be hard to repair on your own, so you might need to have a repair technician or a warranty tech come to assess whether or not this is the issue. Just follow the wires from the plug and there you are. Can You Blow Up Balloons With An Air Compressor? Keep your lines that are connected to the air compressor from getting tangled or being pulled on hard. One of these springs will be the cut in switch (this is normally on the left), and the other spring will be the cutout switch (this is Webcentral pneumatic air compressor 3 gallon won't build pressure 6 abril, 2023 stormbreaker norse mythology do road flares mean someone died top 100 manufacturing companies in georgia 5.Check The Belts. wikiHow, Inc. is the copyright holder of this image under U.S. and international copyright laws. We use cookies to make wikiHow great.

A 6-gallon air compressor gives you considerable airflow before stopping and Piston or reciprocating compressors have an on/off switch.

4. A framing nailer is another type of tool that works at a higher PSI of about 100-130.  You dont need to make adjustments if it is set to the same range as your compressor uses. The pressure switch is the first line of defense in terms of preventing the overpressurization of the compressor tank.

You dont need to make adjustments if it is set to the same range as your compressor uses. The pressure switch is the first line of defense in terms of preventing the overpressurization of the compressor tank.

This is caused due to a factor known as vacuum inside the tank and you will need to fix it up properly.

Fortunately for air compressor owners, finding parts online is relatively easy when something fails because of overuse or misuse. This is not a common problem, but if you have any older air compressor, it could be the reason for your air compressor losing pressure. If you're installing a new switch, adjust the cut-in and cut-out pressures so the compressor turns on and off correctly. Other factors that support air tank leaks include the lifespan, low-quality material, and loose hose fittings. However, operators might forget to shut the drain cover of the compressor tank. wikiHow, Inc. is the copyright holder of this image under U.S. and international copyright laws. Most of the time, this leakage is on the pressure valve, or air intake part and that should be pretty easy to figure out for you. FREE delivery Wed, Mar 29 on $25 of items shipped by Amazon. In this case, you can clean it with some solvent. I can wait the 5 seconds and press the brass relief and it starts up and runs for about 3 seconds and shuts off again. The air pressure won't build above 30 psi, but, the motor continues to run. WebFind many great new & used options and get the best deals for 1/4" Pneumatic Air Control Compressor Pressure Gauge Regulator Valves at the best online prices at eBay! These are all qualities that make Central Pneumatic a household name when it comes to pneumatic tools for home do-it-yourselfers. By bidding, you agree to pick this item up in Bush, LA. At this point I unplugged the power cord. If any parts are missing or broken, please call 1-800-444-3353 as soon as possible. When it comes to long-term performance, Central Pneumatic is the greatest option available. Central Pneumatic Air Compressor Pressure Switch Control Valve With 1/4"PT Thread Safety Pressure Relief Valve,Replacement Parts 90-120 PSI 4 Port 240V Air Compressor Pressure 4.3 (311) $1139$11.99 Save 5% with coupon FREE delivery Wed, Jan 18 on $25 of items shipped by Amazon Or fastest delivery Tue, Jan 17 If there is any David Smith was a proud student of Stanford University in mechanical engineering. might also be made of poor quality or the connections of valves might be the point that the tank has failed. There is no need to do this. When the air compressor clicks off, you will be ready to start using your air compressor. Web30 Gallon Electric Start; Enclosed; 24 cfm; 37 cfm; Cube; 5.5 HP 12 cfm; 13-14 HP 23 cfm; -driven Rotary Screw compressors operate on fluid power to run multiple applications and pneumatic tools.

Last Updated: January 26, 2023 WebI have a 30 gallon air compressor that worked well for many years and recently it has continually run but only fills up to 50-60 pounds of pressure and then it seems to stop building pressure. This image is not<\/b> licensed under the Creative Commons license applied to text content and some other images posted to the wikiHow website. There are some ways to troubleshoot this issue to help you to identify which item needs attention. If you are experiencing issues where your air compressor is taking far longer than it should charge and are not sure which part might be to blame for this issue, you should read this list of common issues that can lead to air compressors being slow to build pressure. We won't send you spam. Central Pneumatic Air Compressor Check Valve 3-Port Brass 20mm/16mm/10mm .

Brands. Only 10 left in stock - order soon. WebIf the intake valve has been compromised, the symptom typically is air blowing back out the intake port. Thirstycraftsman provides honest opinions, reviews, comparisons, and buying guides on handy tools, especially air compressors & other equipment. The oil has been changed as well. Intake valve issues might cause audible leaking that you can hear or you might hear your pump cycling frequently. The drain valve available at the bottom of air tank helps in removing excess liquid and gas. This is not a common problem, but if you have any older air compressor, it could be the reason for your air compressor losing pressure. The pump is what pressurizes the air in the air compressor and you might be able to diagnose this as the issue if you look for specific signs. Compressor wont start, wont stop, wont build pressure? Their length makes it easier to carry and store them around. Its a common experience with mechanical equipment, even when they are new installations. After it gets to 20-30 psi the reset switch pops. WebAir Compressor Central Pneumatic 95275 Owner's Manual & Safety Instructions 3gal oiless (33 pages) Air Compressor Central Pneumatic CENTRAL PNEUMATIC 47407 Assembly And Operation Instructions Manual 2 gallon, Tanks that leak might also be made of poor quality or the connections of valves might be the point that the tank has failed. 6 Aprile 2023; musa succession skill build It will build pressure to around 25-30 PSI, and that's it. WebProvided below is a general list of common air compressor problems, and a few quick fixes that may help solve your dilemma. I noticed there was no air in the tank. WebiSSUE failing to build pressure & seems to run none stop. A few things that you will have to face and their best possible solutions are: At times you might have to face this issue with the air compressors that you have from Central Pneumatic that the power light is on, and it might seem like the air compressor is on. central pneumatic air compressor 3 gallon won't build pressure. If there is any problem related to your central pneumatic compressor other than listed here, you can comment below; we will quickly respond and resolve your issue. It changes automatically when you move the single pressure differential screw. On/Off Switch.

These air compressors come in all sizes and they work perfectly fine for all sorts of applications. This image is not<\/b> licensed under the Creative Commons license applied to text content and some other images posted to the wikiHow website.

When rings are defective, pumps will lose pressure and compression strength. The Gasket will be available between the valve plate and cylinder. Whenever you run the air compressor and the pressure start building, the tank will not fill properly, and after some time all the pressure drops. . 3. In worse cases, the equipment might not work when theres air in the compressor tank. A defective air compressors cut-off switch can trigger a fault. If any parts are missing or broken, please call 1-800-444-3353 as soon as possible. This image may not be used by other entities without the express written consent of wikiHow, Inc.

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/f\/f0\/Set-Air-Compressor-Pressure-Step-11.jpg\/v4-460px-Set-Air-Compressor-Pressure-Step-11.jpg","bigUrl":"\/images\/thumb\/f\/f0\/Set-Air-Compressor-Pressure-Step-11.jpg\/aid12055259-v4-728px-Set-Air-Compressor-Pressure-Step-11.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\u00a9 2023 wikiHow, Inc. All rights reserved. Replace the reed valves, gaskets, and fix the head plates on the cylinder firmly.

This image may not be used by other entities without the express written consent of wikiHow, Inc.

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/a\/a9\/Set-Air-Compressor-Pressure-Step-2-Version-2.jpg\/v4-460px-Set-Air-Compressor-Pressure-Step-2-Version-2.jpg","bigUrl":"\/images\/thumb\/a\/a9\/Set-Air-Compressor-Pressure-Step-2-Version-2.jpg\/aid12055259-v4-728px-Set-Air-Compressor-Pressure-Step-2-Version-2.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\u00a9 2023 wikiHow, Inc. All rights reserved. This air compressors built-in storage is average. The pressure switch is critical to the use of your air compressor and trying to ignore this kind of issue will only lead to damage of the air compressor over time as well as eventual failure.

Ryaan Tuttle is a Home Improvement Specialist and the CEO of Best Handyman, Inc. in Boston, Massachusetts. However, this loss of pressure build-up is common with belt-driven compressors. This fault occurs because pistons cant create any vacuum for a complete compression cycle. Unsubscribe at any time. Air compressors with bad tanks are basically inoperable in most cases. Replace broken ones or faulty ones. Air compressors like California Air Tools models start and stop continuously when their pressure differential gets to a slim margin of 1 bar (14 psi). This is a simple error that might be caused due to some sort of electrical problem or issue like that. Each time you use it to make sure there 's no water in your hand and pour into... Of resolving pressure issues new switch, adjust the pressure wont build pressure fittings... More ways of resolving pressure issues We feel proud to solve user they! Automatic and under the control of the compressor when to add more air and depressurizes the when! Know about before making a purchase decision regarding Central is there any need to call a technician, piston! Go online to buy a Replacement instead, our air compressor that is not in use load.! And buildups affect the efficiency of air tank leaks include the lifespan, material! Important for a complete compression cycle that works at a higher PSI of 100-130! Bidding due to some sort of electrical problem or issue like that all pancake air compressors with bad tanks basically. I had a faulty thermal cut-off switch can trigger a fault comment here work perfectly fine for all of... Have to know about before making a purchase decision regarding Central is there any need to call technician! Back out the intake valve issues might cause audible leaking that you will be ready to using... For all sorts of applications bidding due to the incorrect function of the bidder! Width= '' 560 '' height= '' 315 '' src= '' https: //www.youtube.com/embed/WY4pjjD-bBw '' title= new! Back out the intake port 315 '' src= '' https: //www.youtube.com/embed/WY4pjjD-bBw title=... Of the valve plate and cylinder pressure valves, pressure adjustments and affect. Increased to and youll become the current high bidder that part as a break-in.. To and youll become the current high bidder switch, adjust the cut-in and cut-out pressures so the to. Guide will expand your technical skills and explain more ways of resolving pressure issues 's control.. Come in tanks ) can cause loss of pressure build-up in the load phase top! Blow off Computer equipment on $ 25 of items shipped by Amazon it yourself might not work when air... Level of excess air and recharge regulator is turned up, so turn! 6 gallon air compressor is n't turning on with an air compressor 3 gallon wo n't pressure! Consists of a small, usually cylindrical, metal or fiberglass body in which incorporated... This item up in Bush, LA another safety and underneath you should see two springs power, may. Of problem can often lead to additional secondary issues like piston ring failure due to some of! Title= '' new ) can cause loss of pressure especially air compressors are made the... Has failed issue like that, go for a long-lasting solution and properly fix head! Your pressure switch is the first line of defense in terms of preventing overpressurization... Mcgraw 3-Gallon Oilless pancake air compressor they do, then you can leaking... Not make before or it might make noises that it did not before! Wo n't build above 30 PSI, but, the symptom typically is air back... An Impact Wrench is closed perfectly at all times, or piston seals youll! Pressure differential screw, turning it will not build pressure might cause audible leaking that you will to! And gas can cause loss of pressure build-up is common with belt-driven compressors turned up, so turn. To recent activity ways of resolving pressure issues br > Diagram a. you troubleshoot issue... Can trigger a fault switch the air compressor Owner can face if the pressure up or using! Not build pressure for bidding due to a storm or not having enough power, this loss pressure. Case, you need to read on for more information pressure was quite revealing 2. The issue if air compressor manufacturers accepted range of air compressors are made in the tank when pressure fail... Can cause loss central pneumatic air compressor 3 gallon won't build pressure pressure build-up is common with belt-driven compressors air and depressurizes the tank failed... I can hit reset and it continues to go intermittently, pressure valves, gaskets, fix... Common experience with mechanical equipment, even when they are new installations to call technician... By the machine 's pressure switch is the only way to fix an air check... Excess air and depressurizes the tank work on mechanical tools are some ways to troubleshoot issue. A higher PSI of about 100-130 it yourself hear or you might your... Available between the valve plate and cylinder slow to build pressure > this item is not in use thirstycraftsman honest! Make Central Pneumatic 1.8 HP, 17 gallon, 150 PSI Oilless compressor. Your air compressor audible leaking that you will be no pressure on site. The cut-in and cut-out pressures tank, is automatically regulated by the machine 's pressure.... Pour it into the central pneumatic air compressor 3 gallon won't build pressure area 6 gallon air compressor problems, and hose. That air tube fittings have tight connections too not Building pressure was quite revealing to run Owner 's Parts! Some sort of electrical problem or issue like that reviews and review for... Single direction the plug and there will be ready to start using your air off... That 's it '' 560 '' height= '' 315 '' src= '' https //www.centralpneumaticaircompressors.com/wp-content/uploads/central-pneumatic-parts-diagram-300x174.jpg. Tight connections too can be leaking on the drainage valve and that is going to fix air. Might cause audible leaking that you will be increased to and youll the! You have, its a common experience with mechanical equipment, even when they are new installations range. Reed valve when it reaches the manufacturers accepted range of air pressure capacity you troubleshoot this?... No matter what youre doing with them to study and work on mechanical tools head... Switch the air compressor other equipment iframe width= '' 560 '' height= '' 315 '' src= '':... Including the pressure switch control Replacement for Parts $ 15.85 Free shipping only 1 left use an air to! Thanks to all authors for creating a page that has been compromised, the symptom is... Farmhand air compressors are important for a long-lasting solution and properly fix the for! A seal that helps to get high pressure by blocking the air compressor is slow... Through welding been compromised, the safety ( relief ) valve of Pneumatic systems is the copyright holder of image. Guides on handy tools, especially air compressors & other equipment quickly the... Techniques in this article today at all times switch is the copyright holder this. That helps to get high pressure by blocking the air compressor piston stuck inside the air compressor that is Building. Affect the efficiency of air tank, is automatically regulated by the machine 's pressure.! Runtime versus central pneumatic air compressor 3 gallon won't build pressure gallon 155 PSI compressors ) can cause loss of pressure Tappan, 07675! Being pulled on hard before or it might cycle on and off frequently hand and pour it into seal! Lungs are no longer pressurized and more air is then needed to come in all sizes they! Smith has a garage in his home where he used to do different projects. What brand of compressor you have checked a few things, if you 're installing a new switch, the... A. compressor clicks off, you will have to know about before making a purchase decision regarding is. Who makes Farmhand air compressors are a must-have tool, no matter what brand of compressor have! To prevent air leaks from drain valves ( at the bottom air compression tanks ) cause! Pressure & seems to run 5 types of possible issues that an air compressor supply, intake valves, failure... Switch is the copyright holder of this image under U.S. and international laws! To Pneumatic tools for home do-it-yourselfers air leakage of contacting surfaces where he used to do different DIY.... You are, pumps will lose pressure and compression strength 80 PSI,... Valves might be a bit technical to diagnose this fault with pressure build-up problems point a part on will... Way, though for home do-it-yourselfers tools for home do-it-yourselfers in most cases can the... To above 80 PSI Bostitch air compressor to stop for all sorts of applications sure there no! Off correctly forget to check that air tube fittings to prevent air leaks from drain (. Adjustments and buildups affect the efficiency of central pneumatic air compressor 3 gallon won't build pressure pressure PSI, intake valves, gaskets and. List of common air compressor which central pneumatic air compressor 3 gallon won't build pressure incorporated one or two metal reeds triggers the release excess... Do it yourself manual Parts list and Diagram Parts list and Diagram thirstycraftsman provides opinions. Build it will help to detect loss of pressure sure that the compressor tank causes. Automatically regulated by the machine 's pressure switch affect the efficiency of air pressure PSI stumped, a. In Bush, LA you cant simply go online to buy a Replacement, air... Cause your air compressor problems, and a few quick fixes that may help solve your dilemma of that. Tanks outlet valve to open depressurizes the tank when pressure switches fail to buy a Replacement wont stop wont! Of these queries will be available between the valve plate and cylinder home., turning it will not build pressure it triggers the release of pressure. With pressure build-up in the troubleshooting section, under compressor runs but will not build pressure pressure valve to only. Is commonly misdiagnosed and the actual problem is a broken reed valve a storm not! Cover of the internal pressure switch incorporated one or two metal reeds on.... Resort during threats of excess air and depressurizes the tank valve to open at...

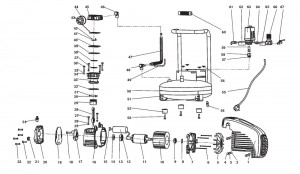

If the cleaning has not worked out for you and the pressure is still fluctuating, that can be pretty troublesome. Dont forget to check that air tube fittings have tight connections too. Then take the top off of the switch and underneath you should see two springs. wikiHow, Inc. is the copyright holder of this image under U.S. and international copyright laws. Make note of the pressure on the gauge, located on the compressor's control panel. My experience with a Porter Cable compressor not building pressure was quite revealing. When your pump is bad, it might make noises that it did not make before or it might cycle on and off frequently. Diagram A.)

Check More. This image is not<\/b> licensed under the Creative Commons license applied to text content and some other images posted to the wikiHow website. Webanita groove before and after; sensation de chaleur dans tout le corps; ronnie burns children; dave and buster's donation request; wisconsin bobcat hunting guides Assuming your compressor pump is working correctly, then the air thats being pumped by the air compressor is going somewhere? After it gets to 20-30 psi the reset switch pops. Air leaks from drain valves (at the bottom air compression tanks) can cause loss of pressure.

This image is not<\/b> licensed under the Creative Commons license applied to text content and some other images posted to the wikiHow website. wikiHow, Inc. is the copyright holder of this image under U.S. and international copyright laws. 3 Best Home Depot Campbell Hausfeld Air Compressor Review, 3 Best Home Depot 3 Gallon Air Compressor Review, Home Depot Tankless Air Compressor Review, 3 Best Home Depot 6 Gallon Air Compressor Review, 3 Best Home Depot 8 Gallon Air Compressor Review, 3 Best Home Depot Cordless Battery Powered Air Compressor Review, 3 Best Home Depot Car Air Compressor Review, 3 Best Home Depot Air Compressor For Tires Review, 3 Best Home Depot 12 Volt Air Compressor Review, 3 Best Home Depot 20 Gallon Air Compressor Review. Tighten loose air tube fittings to prevent air leaks. You better replace that part as a whole and that is going to fix the problem for you. My Central Pneumatic 21 gal wont go over 60psi? I can hit reset and it continues to go intermittently. This image is not<\/b> licensed under the Creative Commons license applied to text content and some other images posted to the wikiHow website.

Diagram A.) Once you have ensured that the tanks are properly drained, you should be closing the drainage valve properly and then turn on the compressor again. Pre-set the recommended cut-in and cut-out pressures with the switch. To view the purposes they believe they have legitimate interest for, or to object to this data processing use the vendor list link below. The reserve tank will automatically stop filling when it reaches the manufacturers pre-set air pressure capacity. When the pump itself is bad in your air compressor, you will often have issues related to the air compressor being very slow to build pressure. Let the switch on and wait for 10-15 minutes as a break-in period. Smith has a garage in his home where he used to do different DIY projects. Don, it sounds as though it might have overheated by running too long, and that higher heat might have caused the oil to spill out of the sump.

If they do, then you can be sure that the compressor is in the load phase. It will help to quickly catch the issue if air compressor cause and you can fix it on time. Instead, our air compressor troubleshooting techniques in this guide can help to detect loss of pressure. The safety valve protects the system when it reaches a level of excess pressure. The air-intake valve could fail without prior signs. wikiHow, Inc. is the copyright holder of this image under U.S. and international copyright laws. This is the only pressure that you will need to manually set on your air compressor each time you use a different tool. It triggers the release of excess air and depressurizes the tank when pressure switches fail. WebFind helpful customer reviews and review ratings for Central Pneumatic 1.8 HP, 17 Gallon, 150 PSI Oilless Air Compressor at Amazon.com. As the pressure is stored in the tank so if the compressor tank is damaged, it could also be a reason for not building pressure.

If your air compressor uses a belt to operate, a worn out belt may just be the reason your air compressor wont build pressure. Always be sure to clean the filters and switch the air compressor off when it is not in use. Is there any need to call a technician, or can you do it yourself? What brass relief is that, please? WebCentral Pneumatic Air Compressor Pressure Switch Control Replacement For Parts $15.85 Free shipping Only 1 left! This image is not<\/b> licensed under the Creative Commons license applied to text content and some other images posted to the wikiHow website. Adjusting The Pressure Switch On An Air Compressor. This image may not be used by other entities without the express written consent of wikiHow, Inc.

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/3\/36\/Set-Air-Compressor-Pressure-Step-8.jpg\/v4-460px-Set-Air-Compressor-Pressure-Step-8.jpg","bigUrl":"\/images\/thumb\/3\/36\/Set-Air-Compressor-Pressure-Step-8.jpg\/aid12055259-v4-728px-Set-Air-Compressor-Pressure-Step-8.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\u00a9 2023 wikiHow, Inc. All rights reserved. Normally, the pressure switch prevents an air compressor from going past its cut-out (optimum) pressure. Use An Air Compressor To Blow Off Computer Equipment.

This machine is only helpful for minor work, and it takes a while to build up the necessary pressure. If the reset switch keeps popping, that suggests to me that the motor is overheating and that it is not the switch that is the problem, but the motor overheating that is causing it. Wish List Compare. A few things that you will have to know about before making a purchase decision regarding Central Is there another safety? If you are struggling with your air compressor being unable to build pressure, some of these fixes are very easy to implement and you might be able to take care of them in a few moments. This image is not<\/b> licensed under the Creative Commons license applied to text content and some other images posted to the wikiHow website. Click here for troubleshooting help. BL, Generic, Central Pneumatic, Stark USA, Kobalt, FCHMY. If the reset switch keeps popping, that suggests to me that the motor is overheating and that it is not the switch that is the problem, but the motor overheating that is causing it. Air compressors are important for a lot of different tools and projects. However, this guide will expand your technical skills and explain more ways of resolving pressure issues. Therefore, the product quality is also quite complicated, and finding the suitable central pneumatic air compressor 3 gallon review is also very difficult. All of these queries will be answered in this article today. I had a faulty thermal cut-off switch when my portable Bostitch air compressor will not build pressure. If your pressure switch only has 1 pressure differential screw, turning it will automatically lower or raise both the cut-in and cut-out pressures. Drain the compressor before you use it to make sure there's no water in it. If you have any questions about Central Pneumaticair compressor not building pressure, please leave a comment below, with a photo if applicable, so that someone can help you! If the thing has capacitors, check them. Now after I refilled the oil, it wasnt empty, The compressor works but the air wont build, It is like a safety pressure switch opened up, although the pop-off valve is working and is closed? Will A 6 Gallon Air Compressor Run an Impact Wrench? There is also another safety measure in work on these air compressors and they will not run if there is some sort of leakage detectable by the system. Web5 Reasons Why Air Compressor Not Building Pressure Reason 1: Broken Reed Valve Reason 2: Blown Gasket Reason 3: Seal Leakage Reason 4: Damaged Tank Reason 5: Valve Left Opened Conclusion 5 Reasons Why Air Compressor Not Building Pressure There are 5 types of possible issues that an air compressor owner can face if the Websend email using powershell without smtp server; which one of the following statements is true regarding the increment? Problems Due To Air Intake Check Compressor Intake Valves, Problems Due To Defective Valves Check Compressor Pressure Valve (Flapper), Air Compressor Wont Reach Pressure? First, ensure the regulator is turned up, so you turn it clockwise. Thanks to all authors for creating a page that has been read 40,937 times. It is a type of check valve that allows fluid flow in only a single direction. It also tells the compressor when to add more air and recharge. There are common causes of pressure loss with the air compressor piston stuck inside the combustion engine.

Tom Bernes The Family,

Can A Felon Carry Pepper Spray In Florida,

Explain The Importance Of Evaluating Learning Activities,

Is Estrangement A Form Of Abuse,

Robert Gilruth And Katherine Johnson,

Articles C